3-D Printing Is Changing the Beauty Product Customization Game

Two years ago, Forbes published a piece about Grace Choi, an inventor who was “taking on the $55-billion makeup industry” by creating a personal 3-D printer that would give women the ability to “print” their own makeup—for real. If you snapped a photo of a fuchsia flower whose hue you’d been coveting, you could then “print” a lipstick in that exact colour. So far, Choi’s Mink printer hasn’t gone to market, but the hype around 3-D technology and beauty hasn’t lessened. Other companies like Foreo and the U.K.’s Adorn are also experimenting with ways to create personalized makeup looks and products. With Foreo’s Moda device, you select a pre-set look—whether it’s from the runway or the red carpet—and place your face into a printer that scans your facial geometry and then prints the look onto your skin via 2,000 superfine nozzles of preloaded mineral makeup “ink.” Adorn is a 3-D makeup pen that scans your face to find your true shade and then prints your foundation in that exact colour.

Though none of these are available to purchase yet and 3-D printing is still in its infancy, having the ability to cook up a smoky eyeshadow right from your own home might not be that far off. Derek Quenneville, a 3-D printing and digital fabrication artist in Toronto, believes that printing cosmetics leverages 3-D printing’s greatest strength: customization. “If someone can bring to market a practical device for generating makeup colours on demand, people will have a greater sense of ownership over their cosmetics,” he says. “The practical ability to create something tied to personal appearance and expression would transform the relationship that people have with cosmetics companies.”

What Quenneville understands is that beauty lovers are in search of customization, which has already gained traction in several industries. I have my initials and an ice cream emoji etched on my Vianel leather iPhone case, and when Coke came out with the “Share a Coke” campaign, replacing its logo with names, I was gutted when I couldn’t find mine. When it comes to cosmetics, Toronto’s Bite Beauty has been at the forefront of personalization with its custom lipsticks, available at their Lip Labs in New York and the newly opened flagship in the brand’s hometown. If my phone, soft drink and lipstick shade can be customized, why can’t my cosmetics case be, too?

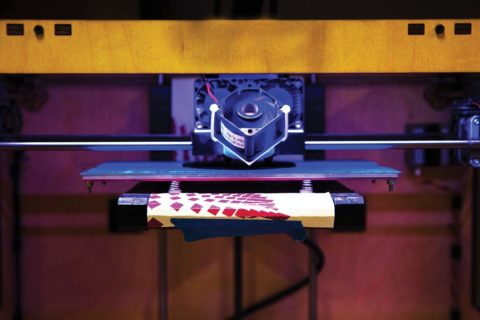

So with the help of Hot Pop Factory, I decide to print my own personalized powder compact. The laser-cutting and 3-D printing studio works with individuals and companies—from fashion designers to automakers—to customize products, such as precision-cut leather belts and small-scale car parts. In the Toronto studio, there are miniature plastic objects scattered across the work table, large computers projecting 3-D designs and machinery. In front of me is a low-resolution 3-D printer, which can only be described as a box with an ink cartridge hanging in the middle of it. The cartridge goes round and round, making what looks like a flat black circle.

“Imagine someone taking icing and squeezing it out of a tube,” says Biying Miao, Hot Pop Factory’s co-founder, “but it’s happening on a micro-scale, where each line of icing is a fraction of a millimetre. After a while, it’s going to build up into a 3-D shape.”

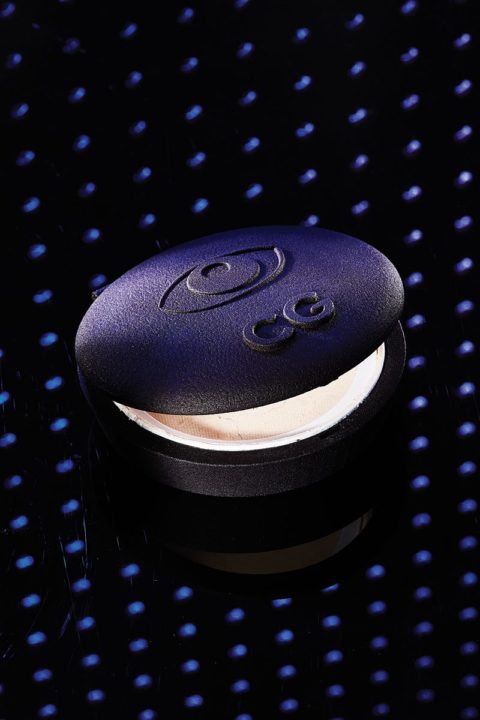

This is just the low-resolution version, so Miao leads me over to one of the large-screen computers, where she shows me a design of what my finished powder compact will look like. (I sent her compact inspo before we met.) It’s entirely matte black, and the top enclosure features my initials, “CG,” and an eye emoji that I love. Inside there’s a mirror (engraved with my initials) and space for whatever powder refill I choose. The entire compact will be made by what Miao calls “a suite” of robots: The 3-D printer will churn out the plastic enclosures, while a laser will cut the mirror and engrave my initials onto the glass.

When I get the final compact, which takes about 48 hours to complete, I’m impressed at how similar it is to the design Miao showed me on the computer. The plastic material is dense and usable—surprising, considering the entire thing started out as powder in a high-resolution 3-D printer. Although the compact is bulkier than what I’d usually buy, I adore it because I made it.

I have visions of a future in which I’m able to go to the makeup counter at Sephora and have “CG” printed on any of my purchases on demand. Imagine personalizing beauty products online with 3-D-printed letters, shapes, colours and patterns? Better yet: What if we could replicate a beloved but discontinued shade instead of stalking it on eBay?

Miao believes that this is where the beauty industry is headed. “If we’re using these robots to make products one at a time and maybe it’s slightly more expensive than doing it the mass-produced way, the extra value comes from you having your emoji and your initials on the cover—it’s completely for you,” she says. “Every single one can be different. And that means that each consumer can get exactly what they want made especially for them.”

The post 3-D Printing Is Changing the Beauty Product Customization Game appeared first on FASHION Magazine.